Voortman MO Heavy-Duty Series Pipe Cutting and Processing Machines

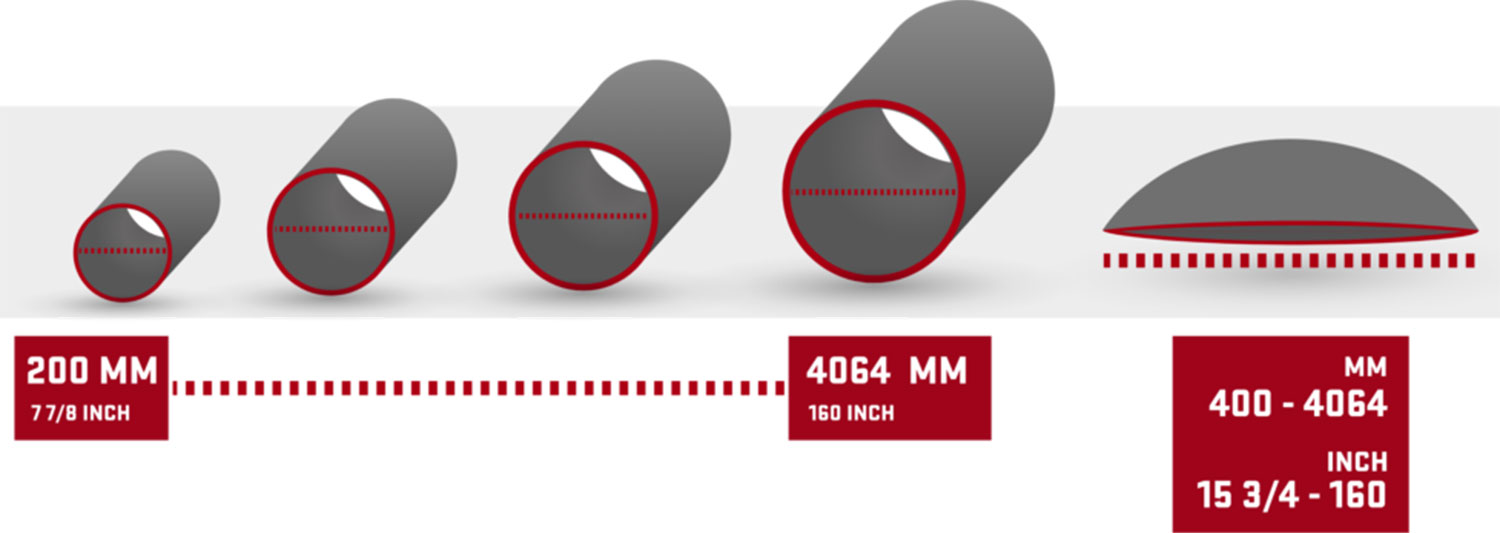

The Heavy-Duty pipe cutter for large diameter pipes up to 160″

CALL FOR QUOTE OR DETAILS – 877-724-7297

VOORTMAN MO HEAVY-DUTY SERIES

– 2000, 2500, 3000, 4000

TILTABLE HYDRAULICALLY ROTATING CHUCK

The thermal cutting of dishes can easily be done on the machine. It saves you lots of handling time and brings high quality cuts in dished ends. To execute cutouts (holes) with weld bevel preparation on dished ends the machine needs to be equipped with a tiltable chuck which is hydraulically rotated from its standard position through 90° onto its back. This tilted chuck can then take and clamp dished ends with the same minimum and maximum diameters as round pipes while saving you extra working space.

POWERED HEIGHT ADJUSTMENT OF THE OPERATORS PLATFORM

Large-diameter pipes often obstruct the machine operator’s view and hence his control of the ongoing cutting process. On the Heavy-Duty series, the solution is an operator’s platform on the cutting carriage that can be raised and lowered together with the computer in accordance with the required height of vision during the cutting process.

- Complex pipe cutting on large diameter pipes, pressure vessels, heat exchangers, boilers and tanks

- Round pipes and/or dished ends with a maximum diameter of up to 4,000 mm / 160″ and up to a pipe weight of 45 metric tons

- Equipped with 6 CNC-controlled axes

- 3D cutting performed with plasma and oxy-fuel

- Extreme solid design

- High-quality, reliable and accurate pipe profiling

Large Diameter Pipe Cutting & Processing up to 160″

Supported Processes

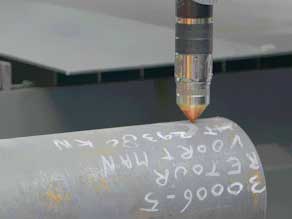

PLASMA CUTTING

3D-BEVEL CUTTING

OXY-FUEL CUTTING

PLASMA MARKING

Features & Processes For Pipe Carriage

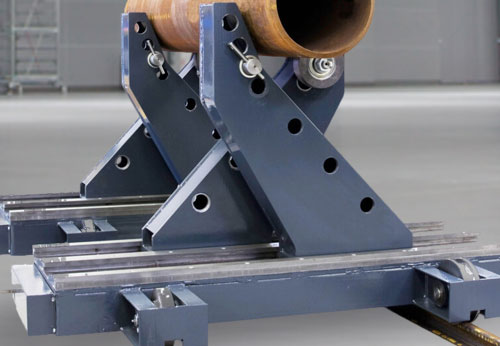

Mechanical Pipe Carriage With Manual Scissor-Type Adjustment

This very solidly designed pipe carriage supports the pipe with scissor-type carriers. It is designed for a load of 7.5 tonnes, depending on machine size. The pipe carriage is adapted to different pipe diameters with a manually operated spindle adjustment mechanism.

Hydraulic Pipe Carriage With Electrical Height Adjustment

This very solidly designed pipe carriage supports the pipe with a hydraulically height adjustable roller bed. The hydraulic height adjustment can be manually or electrically operated. It is designed for a load of 10, 12 or 15 tonnes, depending on machine size.

Motorized Drive System (X-Axis) For Pipe Carriage

For heavy pipes, the pipe carriage can be optionally equipped with a pneumatic motor. By actuating a lever attached to the pipe carriage, the pipe carriage can then be driven and braked by the motor.

Voortman MO Heavy-Duty Series Pipe Cutting Machine Features and Processes

FEATURES & PROCESSES FOR CUTTING

- Torch head

- Electromechanical tracer

- Slide system

- Oxy-fuel cutting package

- Preheating torch

- Plasma cutting

- Module for cutting cones

FEATURES & PROCESSES FOR MARKING & PRINTING

- Needle marking system (airscriber)

- Needle printing system

- Label printing

- Plasma marking system

- Inkjet marking and printing system

FEATURES & PROCESSES FOR PIPE CARRIAGE

- Mechanical pipe carriage with manual scissor-type adjustment

- Hydraulic pipe carriage with electrical height adjustment

- Motorized drive system (x-axis) for pipe carriage

Voortman MO Heavy-Duty Series Specifications

- Weight of standard machine (lbs): 39683.207 to 61729.433

- Number of CNC axes (axes): 6

- Max. workpiece weight (lbs): 88184.905

- Min. – max. clampable round pipe diameter (inch): 7 7/8 – 80 to 7 7/8 – 160

- Min. – max. cuttable workpiece length (inch):

11 13/16 – 472 7/16 to 11 13/16 – 472 7/16 - Min. – max. wall thickness for cutting with oxy-fuel/plasma (inch):

3/16 – 7 1/16 / 1/16 – 3 1/8 to 3/16 – 7 1/16 / 1/16 – 3 1/8 - Max. size of chuck opening (inch): 47 1/4 to 59 1/16

- Min. – max. clampable diameter for dished ends (inch): 15 3/4 – 80 to 15 3/4 – 160

- Max. torch angle (degrees): +/- 70 / 45

As Voortman Machinery Specialists we can help you make the right choice!

877-724-7297

Contact us today for a quote or to learn more about the industry’s leading large diameter pipe cutting systems.

Contact us at 877-724-7297, or fill out our web form below.