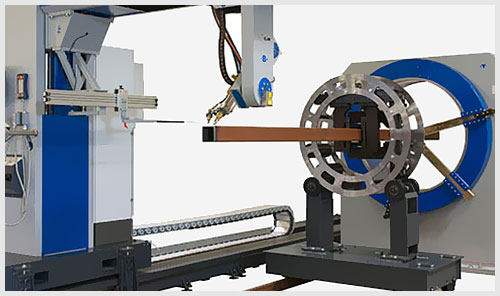

Voortman MO Classic Series Pipe Cutting Machines

Versatile Pipe Cutting Machines for complex shapes from 2″ to 80″

CALL FOR QUOTE OR DETAILS – 877-724-7297

VOORTMAN MO CLASSIC SERIES

– 600, 1200, 1500, 2000

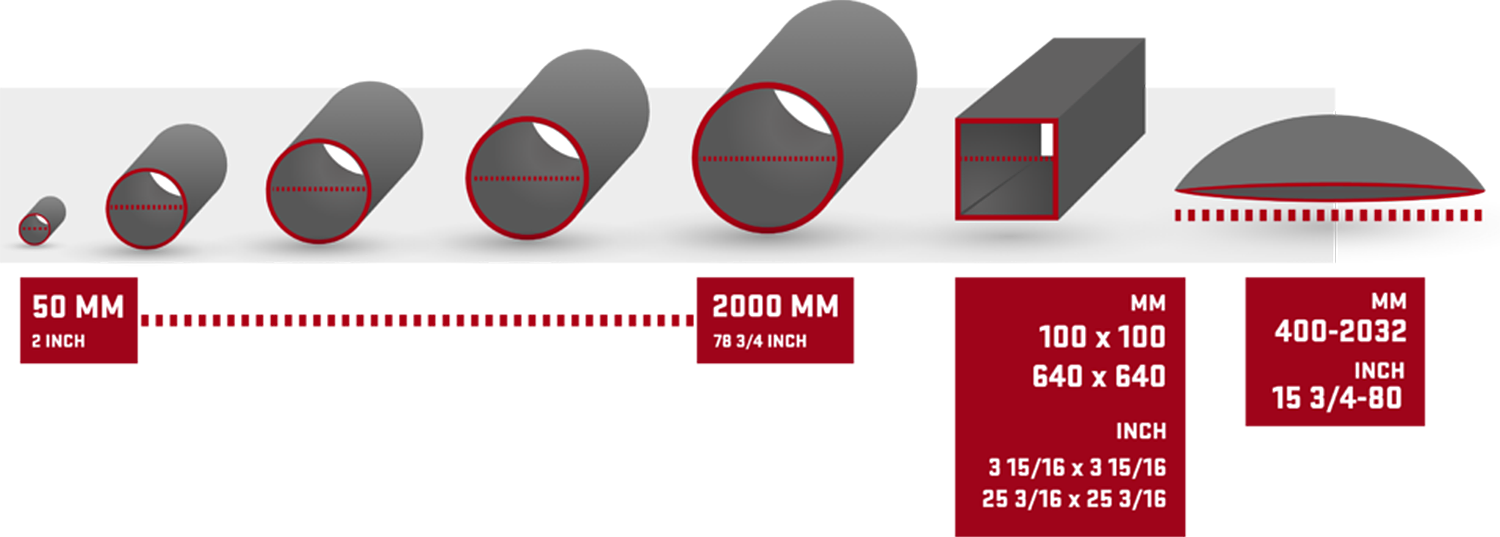

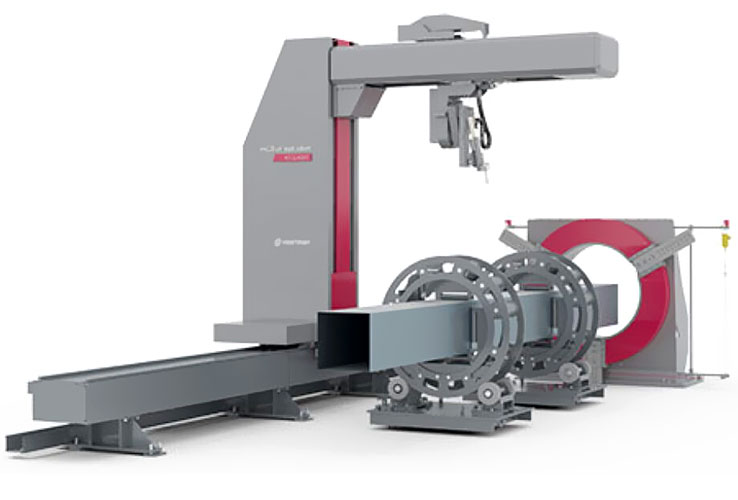

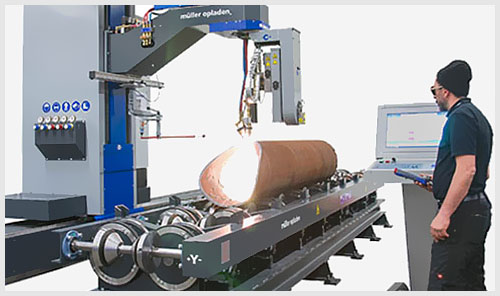

The Voortman MO Classic Series covers their classical machines primarily for round pipes with a maximum diameter of up to 2.000 mm / 80″ and up to a pipe weight of 30 tons. This machine series is offered in different models. This series is also suitable for square, rectangular pipes and dished ends optionally.

Thanks to numerous technical optional extras, these complex machines can be individually adapted to customer’s specific needs. The various machines of the MO Classic Series can be equipped with up to 7 CNC axes. The machine is built with six standard CNC axes, perfect for round workpieces. However, when it comes to cutting square and rectangular pipes, an optional seventh CNC axis is necessary.

- Versatile and highly accurate Pipe Cutting Machine

- Multi processes with plasma and oxy-fuel

- Round pipes up to 2.000 mm / 80″, square and rectangular pipes up to 640 x 640 mm, vessel heads up to 2.000 mm / 80″

- Equipped with 6 or 7 CNC-controlled axes. Adding the optional 7th CNC axis allows you to cut squared & rectangular pipes

- 3D cutting performed with plasma and oxy-fuel

Pipe Cutting & Processing from 2″ to 78″

Supported Processes

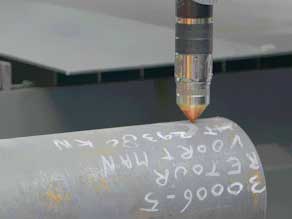

PLASMA CUTTING

3D-BEVEL CUTTING

OXY-FUEL CUTTING

PLASMA MARKING

Extension of Machine Functions

Rollerbed Pipe Carriage

The MO-Classic Rollerbed covers our classical machines without the need for a chuck clamping system, primarily for round pipes with a maximum diameter of up to 1.500mm (60″) and up to a pipe weight of 24 tons. Reduce dead zones, save material and increase margins.

Square & Rectangular Cutting

The thermal profiling of square and rectangular pipes is possible in addition to cutting round pipes. To achieve the cut contours on square and rectangular pipes, the machine is extended by a transverse axis (7th CNC axis).

Thermal Dome & Dish Cutting

Provides high quality cuts in dished ends. The machine is equipped with a tiltable chuck which is hydraulically rotated from its standard position onto its back, which can then take and clamp dished ends with the same diameters as round pipes while saving you work space.

Voortman MO Classic Series Pipe Cutting Machine Features and Processes

FEATURES & PROCESSES FOR CUTTING

- Torch head

- Electromechanical tracer

- Slide system

- Oxy-fuel cutting package

- Preheating torch

- Plasma cutting

- Module for cutting cones

FEATURES & PROCESSES FOR MARKING & PRINTING

- Needle marking system (airscriber)

- Needle printing system

- Label printing

- Plasma marking system

- Inkjet marking and printing system

FEATURES & PROCESSES FOR PIPE CARRIAGE

- Hydraulic pipe carriage with manual scissor-type adjustment

- Chuck height adjustment

- Fixed-height pipe carriage with manual adjustment of rollers

- Manual ball cutter

- Motorized ball cutter

- Hold-down device

- Carriage for square and rectangular pipes

- Mechanical pipe carriage with manual scissor-type adjustment

- Floating chuck

Voortman MO Classic Series Specifications

- Weight of standard machine (lbs): 15432.36 to 28660.09

- Number of CNC axes (axes): 6 to 7

- Max. workpiece weight (lbs): 26455.47 to 44092.45

- Min. – max. clampable round pipe diameter (inch): 2 – 24 to 3 1/8 – 80

- Max. size of chuck opening (inch): 15 3/4 to 37 3/8

- Min. – max. clampable square & rectangular pipes dimension (inch):

3 15/16 x 3 15/16 – 9 7/16 x 9 7/16 to 3 15/16 x 3 15/16 – 25 3/16 x 25 3/16 - Min. – max. cuttable workpiece length (inch):

11 13/16 – 944 7/8 to 11 13/16 – 944 7/8 - Min. – max. wall thickness for cutting with oxy-fuel /plasma (inch):

3/16 – 5 15/16 to 1/16 – 3 1/8 - Max. torch angle (degrees): +/- 70 / 45

As Voortman Machinery Specialists we can help you make the right choice!

877-724-7297

Contact us today for a quote or to learn more about the industry’s leading large diameter pipe cutting systems.

Contact us at 877-724-7297, or fill out our web form below.