Voortman V505-160M, V550-7, V505-160T Flat and Angle Processing Lines

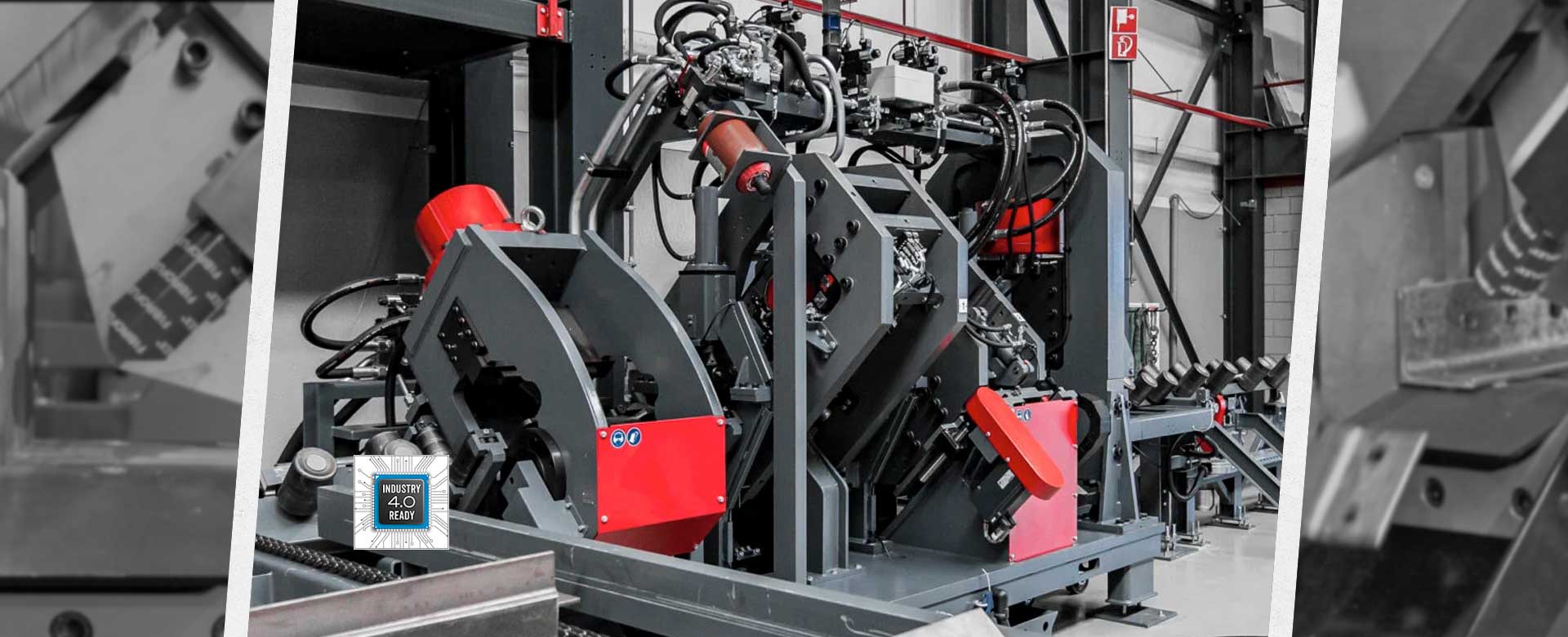

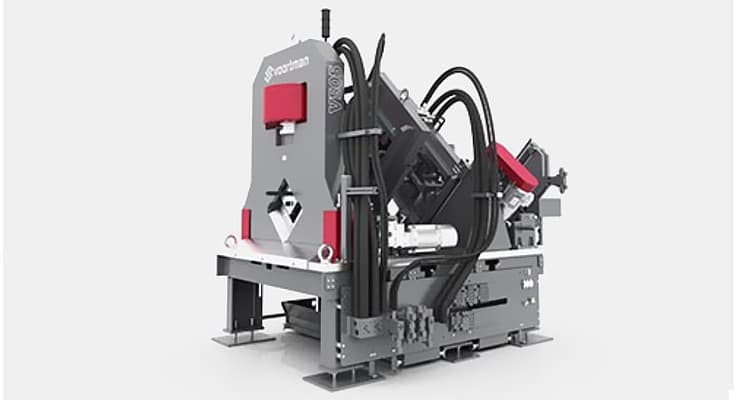

Voortman V505M Punch and Shear Angle Line

Flat & Angle Punching And Shearing

The V505-160M punching and shearing machine was specifically designed with the needs of steel fabricators in mind for high output production. The V505-160M can process flat bar as well as angles for added versatility. The hydraulic system is optimized for high volume and maximum pressure and flow. It can punch and shear extremely fast.

Features

- Robust O-frame for increased rigidity.

- Automated infeed and outfeed.

- Clip angles.

- Flat bar processing.

- Made for steel fabricators.

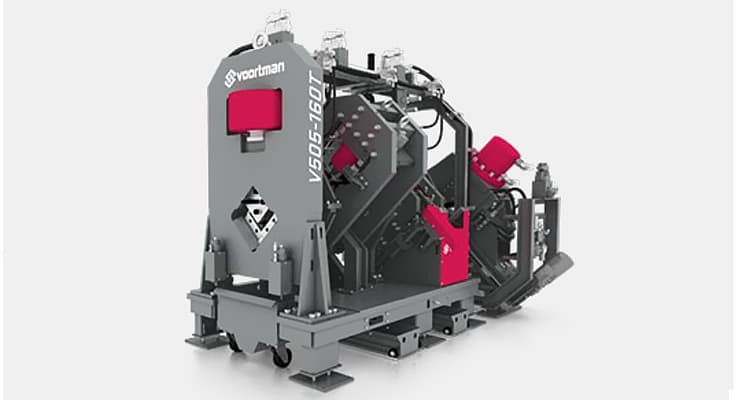

Voortman V505-160T Punch and Shear Angle Line

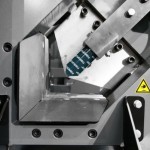

Angle Punching And Shearing

The Voortman V505-160T CNC angle punching, shearing and drilling machine is designed with speed and stability in mind for maximum output and quality when processing angle bar. The machine’s processing speed and automated features guarantee a significant improvement in productivity. The V505T optimizes material efficiency by processing with minimal scrap. The machine’s robust construction ensures optimal results.

Features

- Robust bridge for increased rigidity.

- Automated infeed and outfeed.

- Up to 2 drilling and 2 punching units.

- Servo driven feeder clamp for high precision.

- 10-station automatic toolchanger (optional).

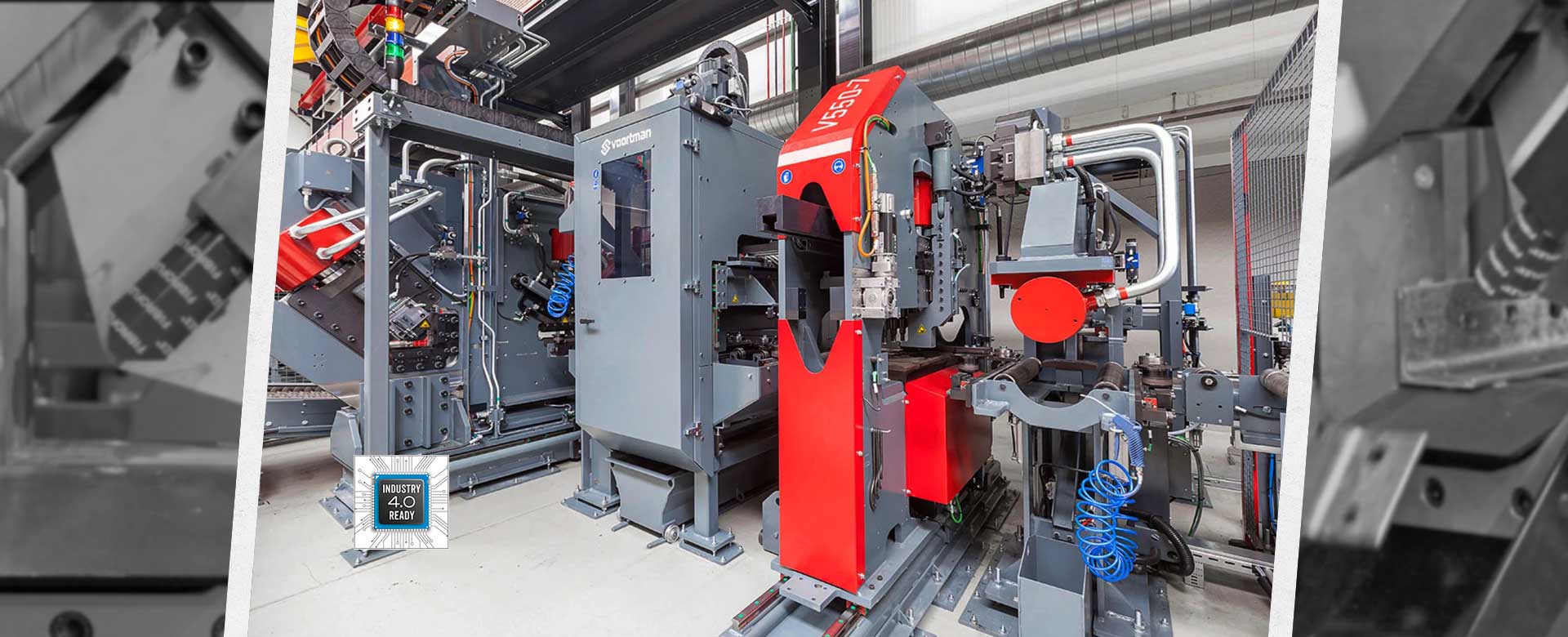

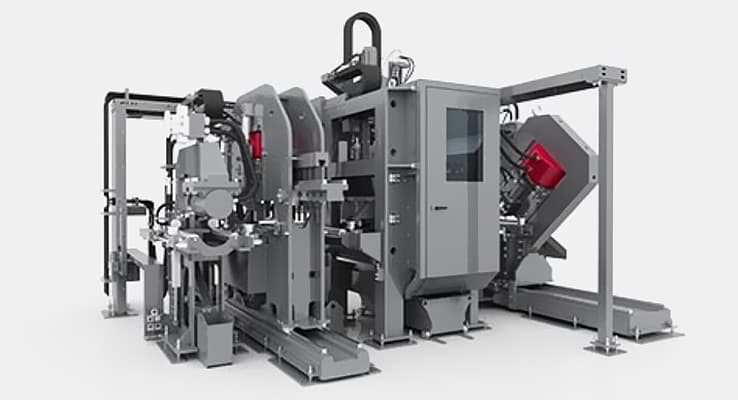

Voortman V550-7 Punch, Shear, Drill, Mark Angle Line

Flat & Angle Punching, Shearing, Drilling & Marking

Victory Rail & Gantry systems include True Hole, which was designed from the ground up to give you the best possible plasma-cut hole. Each of our industrial CNC Rail Systems are built in house and ships complete, with plasma cutter and controller installed and fully tested prior to shipment.

Features

- Additional drilling capabilities.

- Automatic die and punch selection.

- Layout marking & part identification.

- Automatic infeed buffering.

- Optional automatic outfeed sorting system.

100% FULL AUTOMATION

Voortman’s VACAM software provides full automation from start to finish. Once the material is laid on the infeed cross transfers, it’s path through the entire line of connected machinery is controlled entirely by the automated system. This level of automation eliminates human errors and inefficiencies made by machine operators. VACAM is an open platform allowing an API to exchange production information between VACAM and ERP/MRP packages. End users can monitor production times in real-time. Production data is saved so that it can be compared to bid data.

Looking for the right angle iron system for your needs? – 877-724-7297

We can help! We offer Voortman CNC Angle Iron Machines.

Contact us at 877-724-7297, or fill out our web form below.