AMOB Electric Pipe & Tube Benders

MDH 90 & 60 Pipe & Tube Benders

Cost-effective Simplicity, Strength and Accuracy

The AMOB MDH series (NC electric pipe and tube benders) is the company’s standard-issue range – simplicity, strength and accuracy are the key features of this extremely cost-effective line. Ideal for prototyping or small to medium projects, MDH are easily adapted to each different industrial and non-industrial situation.

These versatile machines are an easy and obvious choice for those starting up a tube bending or handrail business, or to complement heavy production or prototyping divisions. The MDH series allow for bending complex tube geometries within seconds of programming. Machines from this range are are all equipped with AMOB NC touchscreen easy to operate controls.

Features

- Hydraulic mandrel extractor.

- NC1 or NC2 axis.

- Hydraulic clamp and pressure die.

- Easy to operate controls.

- AMOB NC touchscreen.

- 10mm up to 90mm OD.

MDH 90 Technical Data

- Max. capacity – 90 x 4 mm

- Y axis accuracy – ± 0,1

- Z axis accuracy – ± 0,05

- Max. Bending Radius – 305 mm

- Machine Useful Length – 3000 mm

- Installed Power – 8 KW – 8.25 KW

MDH 60 Technical Data

- Max. capacity – 60 x 3 mm

- Y axis accuracy – ± 0,1

- Z axis accuracy – ± 0,05

- Max. Bending Radius – 195 mm

- Machine Useful Length – 3000 mm

- Installed Power – 6.2 KW – 6.4 KW

Starbend Hybrid Pipe & Tube Benders

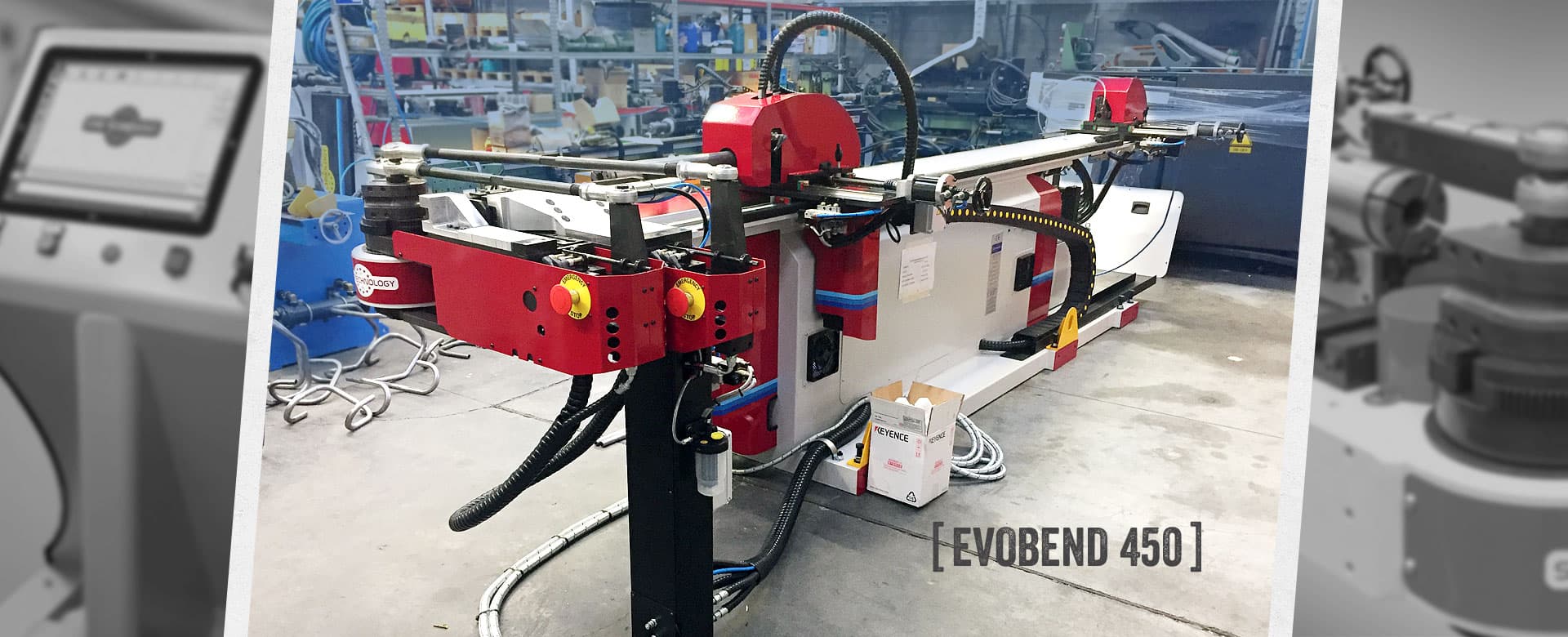

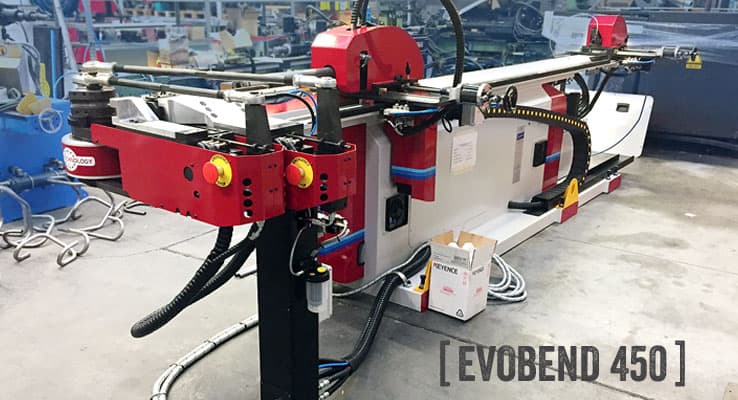

Star 800 & 450 EVOBEND Pipe & Tube Benders

Exclusive Tube Bender Control System

The EVOBEND pipe and tube bending line was created to combine price, quality and design which culminates in the best 3-Axis automation solution. Exclusive tube bender control system; simple to program in LRA with custom import features from CMM’s or text files. With active 3D part simulation. A perfect machine for handrail processing.

Features

- All essential components manufactured in carbon steel.

- Primary axis movement driven by brushless motors.

- Power transmission guaranteed by planetary gearboxes.

- Bending head overhang for greater flexibility.

- Absolutely irreversible toggle lock closure.

- Simple regulation of Shoulder/Clamp opening.

- Quick connection of the Following block/Roller holder.

- Predisposition for split die cylinder up/down.

- Master collet insert for rapid change-out.

- Programmable mandrel extraction anticipation angle.

- Compact console 15” touch screen and S.T.I. interface.

- Collet push during bending cycle.

- Push bending and interpolation bending.

- Interchangable been shaft.

- Automatic management of different bending styles; closed collet and through collet bending.

800 EVOBEND Technical Data

- Max tube / mild steel round – 80×5 mm

- Max bending radius – 320 mm

- Max push length – 4200 mm

- Useful length over mandrel – 6000 mm

- Max bar passage inside the P.O.B. positioner – 76 mm

- Dimension under the bending head – 515 mm

- Bending head overhang – 515 mm

- Bending head interface radius – 200 mm

- Operating power 3 phase – 400/480 V

- Operating frequency – 50/60 HZ

- Approx. weight – 6000kg

- Bending direction: Left or right

- Bender dimensions – 1750×7300 H1550 mm

450 EVOBEND Technical Data

- Max tube / mild steel round – 80×5 mm

- Max bending radius – 320 mm

- Max push length – 4200 mm

- Useful length over mandrel – 6000 mm

- Max bar passage inside the P.O.B. positioner – 76 mm

- Dimension under the bending head – 515 mm

- Bending head overhang – 515 mm

- Bending head interface radius – 200 mm

- Operating power 3 phase – 400/480 V

- Operating frequency – 50/60 HZ

- Approx. weight – 6000kg

- Bending direction: Left or right

- Bender dimensions – 1750×7300 H1550 mm

We go beyond the selling points of our leading edge products

We look to ensure the success of your new purchase by working with you to identify and enhance efficiencies throughout your entire processing line.

Contact us at 877-724-7297, or fill out our web form below.